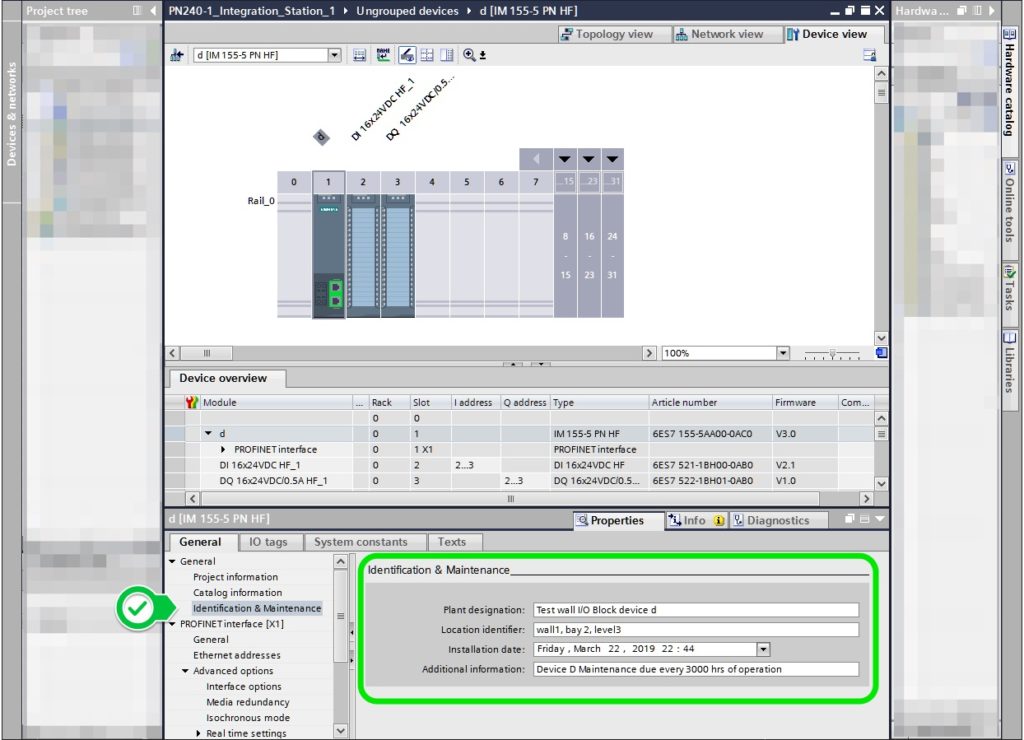

Identification and Maintenance functions (I&M) allow access to blocks of data kept inside each PROFINET device by use of acyclic read / write record requests. Keeping the data internal to the device allows the control engineer to differentiate similar devices across the network. Things like device name, location in the factory, maintenance information for this device, etc. can be stored in each device. These records can be written with a programming tool , an engineering tool, or via read/write record requests under application program control.

- I&M0 data is “built-in” by the manufacturer and is read-only

- I&M1 through I&M3 can be written to a device’s memory by the control engineer to aid in documentation

- I&M4 is used by PROFIsafe devices

- I&M5 provides additional manufacturer information about the device

User writable I&M records (I&M1-3) are persistent and will remain until they are changed or until the device is reset to factory settings (cleared).

| I&M record | Usage | Access | Modified by |

|---|---|---|---|

| I&M0 | Manufacturer data | Read only | - |

| I&M1 | Tag Information | Read/Write | Engineering tool / programming package |

| I&M2 | Date/Time | Read/Write | Engineering tool / programming package |

| I&M3 | Description | Read/Write | Engineering tool / programming package |

| I&M4 | Reserved for PROFIsafe | Read only | - |

| I&M5 | Optional Manufacturer data | Read only | - |

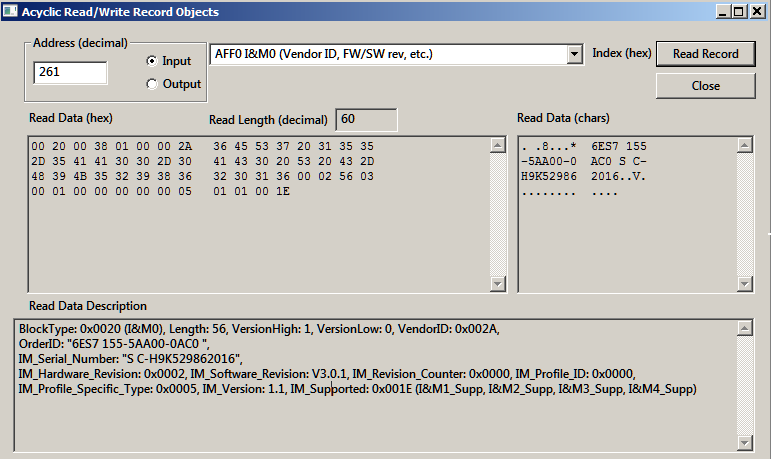

I&M0 is a Read-Only Data Record Provided by the Device Manufacturer

I&M0 data is permanently stored inside the device by the device vendor, this data is related to the device application layer. The following table shows the contents of I&M0.

| Field | Description | Definition |

|---|---|---|

| VendorID | Vendor Identification number | Vendor ID of device manufacturer (assigned by PI) |

| OrderID | Order ID of the device | This is the Order ID, or model number or SKU number of the device. It is assigned by the vendor and should be equal to customer readable markings on the device. |

| IM_Serial_Number | Serial number of the device | This must be a unique serial number of the device. It should be the same as the serial number markings on the device. |

| IM_Hardware_Revision | Hardware revision of the device | This must be equal to hardware designation markings on the device. |

| IM_Software_Revision | Software revision of the device | The version refers to the entire device, including PROFINET protocol implementation and the device application. It should be changed whenever a part of the software in the device is changed. |

| IM_Supported | Bitmask that defines which I&M fields are supported by the device | See above table for what each I&M record represents. |

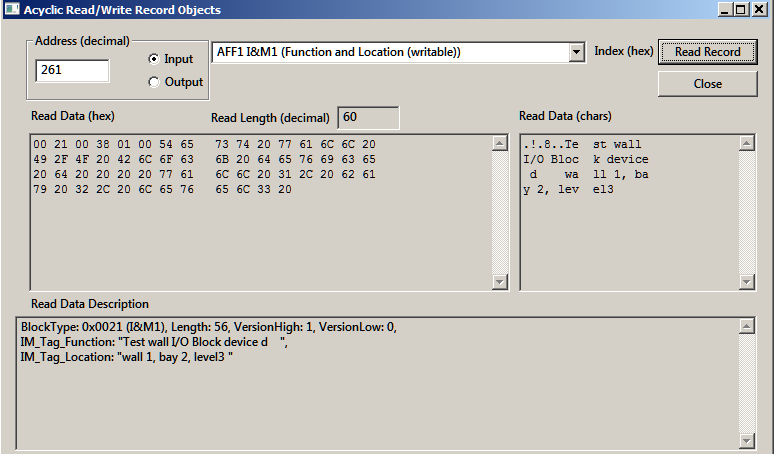

I&M1 – I&M3 are User Writeable Data Areas

I&M1 contains 2 fields: Tag-function and Tag-location. “Tag function” is a 32 byte visible string that indicates the submodule’s function or task. “Tag location” is a 22 byte visible string that indicates the submodule’s location. This information is available for use by the end user/system engineer to save local documentation to allow differentiation from other devices in the system.

I&M2 is a Date and time function in the YYYY-MM-DD HH:MM format. For example, 2018-08-10 10:50 denotes August 10, 2018 at 10:50 AM. This information is available for use by the end user/system engineer to save time information for this specific device internally.

I&M3 is a general “Descriptor” function that is a 54 byte visible string for holding additional information. This information is available for use by the end user/system engineer to save local documentation specific to this device.

These I&M records may be written during the programming process to write the records into the device.

I&M4 is Reserved for Use by PROFIsafe (Functional Safety)

You can find more information on I&M4 and its’ uses in the Functional Safety area of PROFINET University.

I&M5 is a Read-Only Data Record Provided by the Device Manufacturer

I&M5 is optional. When present, I&M5 data describes the communication manufacturer. It references the stack vendor or comm chip stack vendor. It might not be unusual for two PROFINET devices from different vendors to report the same third party vendor in their I&M5 data. I&M5 data is all about the interface vendor.

I&M Summary

Identification and Maintenance functions are implemented in every PROFINET device. This information can be particularly useful since it is accessible across the network. From the control room or the maintenance room, I&M information is available for helping to maintain your installation.

If you are developing a PROFINET device and would like to know more about implementing PROFINET I&M functions, you can find more information in the PROFINET Services Specification that’s available as part of the PROFINET Test Bundle.

Gain a deeper understanding of PROFINET by attending a PROFINET Certified Network Engineer Course.

Gain a deeper understanding of PROFINET by attending a PROFINET Certified Network Engineer Course.

These certification classes are intense, hands-on courses. You will learn how the underlying technology works from the application to the frame level. After passing both a practical and written exam, you become certified.

For more information, contact us or visit our website.