PROFINET device parameters are features that can be selected to set the operating conditions of a device. PROFINET supports 3 types of parameters: Standard parameters, F-parameters, and Dynamic Parameters. The GSD file of each device defines its parameters (GSD files are explained in PROFINET GSD File Basics).

Three Types of Device Parameters

1) Standard Parameters

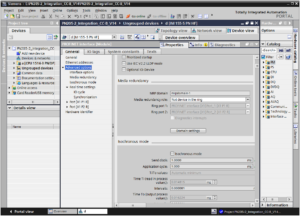

Standard parameters are available for each device. The PROFINET Controller configuration tool displays the available  parameters and allows the user to make selections. Once the parameters are set they will be stored in the IO controller and downloaded to the device when a connection is established. Some examples of standard parameters include: MRP settings, send clock, device watchdog time, start-up mode, and device diagnostic selections. Namely, device diagnostic parameters such as wire break, no supply voltage, short circuit, etc. The following figure on the right shows part of a device parameter selection screen.

parameters and allows the user to make selections. Once the parameters are set they will be stored in the IO controller and downloaded to the device when a connection is established. Some examples of standard parameters include: MRP settings, send clock, device watchdog time, start-up mode, and device diagnostic selections. Namely, device diagnostic parameters such as wire break, no supply voltage, short circuit, etc. The following figure on the right shows part of a device parameter selection screen.

2) F-Parameters (Failsafe Parameters)

F-Parameters (Failsafe related parameters) are only available if the device and the controller both support PROFIsafe. Safety parameters are embedded inside the standard parameter packet using the same technique used for PROFIsafe F-IO data embedding (see PROFIsafe Profile Details). The following table describes F-Parameters in detail.

F-ParameterBlock

| Parameter Name | Byte address | Data type | Definition |

|---|---|---|---|

| F_PRM_Flag1 | 0 | Unsigned8 | byte field with bits that represent, iPar present, F SIL (Safety Integrity Level) level, F-CRC length |

| F_PRM_Flag2 | 1 | Unsigned8 | byte field with bits that represent F-Par Version, iPar present |

| F_Source_Add | 2-3 | Unsigned16 | Safety address (F-Address) of F-Host |

| F_Dest_Add | 4-5 | Unsigned16 | Safety address (F-Address) of F-Device |

| F_WD_Time | 6-7 | Unsigned16 | F-Watchdog time based on a 1ms time base |

| F_iPar_CRC (optional) | 8-11 | Unsigned32 | 4 byte CRC for iParameters (if no iPars this field is empty) |

| F_Par_CRC | 12-13 | Unsigned16 | 2 byte CRC across the F-Parameter block(and the iPar block if it is present) |

3) Dynamic Parameters ( iParameters)

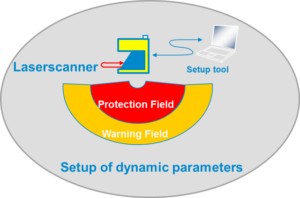

With some field devices, complete parameter assignment through GSD files is not very useful due to the amount of data, the direct user guidance needed, or the specific circumstances in an automation system. Dynamic parameters device or plant-specific data. In most cases, the user must assign these parameters during device commissioning. For example, some safety lasers scanners require a special setup tool to define the protective fields. These field definitions are specific to the location of the scanning device. In case of device replacement, the setup tool is required during recommissioning.

the direct user guidance needed, or the specific circumstances in an automation system. Dynamic parameters device or plant-specific data. In most cases, the user must assign these parameters during device commissioning. For example, some safety lasers scanners require a special setup tool to define the protective fields. These field definitions are specific to the location of the scanning device. In case of device replacement, the setup tool is required during recommissioning.

When replacing a field device with dynamic parameters, it would be preferable to automatically reload these parameters into the new field device on voltage recovery rather than recommissioning by hand. PROFINET offers unique support for this type of device with iParameters and the iPar-Server. After the device commissioning a database can store all the dynamic data (iPars) for the future.

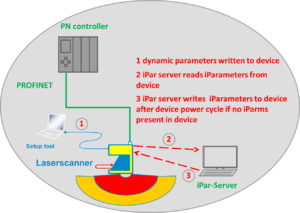

iPar-Server

The iPAR-Server is an entity that handles the upload of iPars from the device. It  stores them and can restore them to the device upon device replacement. The adjacent figure shows the iPar server operation. By using the iPar-Server to save and automatically upload these dynamic device parameters, the user avoids additional commissioning time and cost. Although iPars and the iPar server are not requirements for any device, they are features that a vendor can choose to support since they make device replacement easier.

stores them and can restore them to the device upon device replacement. The adjacent figure shows the iPar server operation. By using the iPar-Server to save and automatically upload these dynamic device parameters, the user avoids additional commissioning time and cost. Although iPars and the iPar server are not requirements for any device, they are features that a vendor can choose to support since they make device replacement easier.

PROFINET Device Parameter Support

In summary, Device GSDML files support the three types of PROFINET device parameters; standard, F-parameters, and Dynamic parameters. PROFINET Controller programming tools use the GSDML information and allow end users to choose PROFINET device operating details.

Do you want to learn more about PROFINET?

Do you want to learn more about PROFINET?

The PROFI Interface Center has you covered with PROFINET Certified Network Engineer classes.

Our certification classes are intense, hands-on courses. You will learn how the underlying technology works from the application to the frame level. After passing both a practical and written exam, you become certified.

For more information, contact us or visit our website.