It’s three A.M. Third shift is in full swing when a distributed I/O rack decides to stop working. But instead of stopping the line, the system seamlessly switches over to the redundant I/O rack and just logs a “maintenance requested” message with the operator. The maintenance crew doesn’t have to scramble, and the night continues without a hitch. That’s device redundancy in action.

Device Redundancy usually requires the devices to be connected to a common set of I/O wiring. The devices must be coordinated to prevent them from driving the same set of outputs at once.

PROFINET Device Redundancy moves responsibilities to the controller

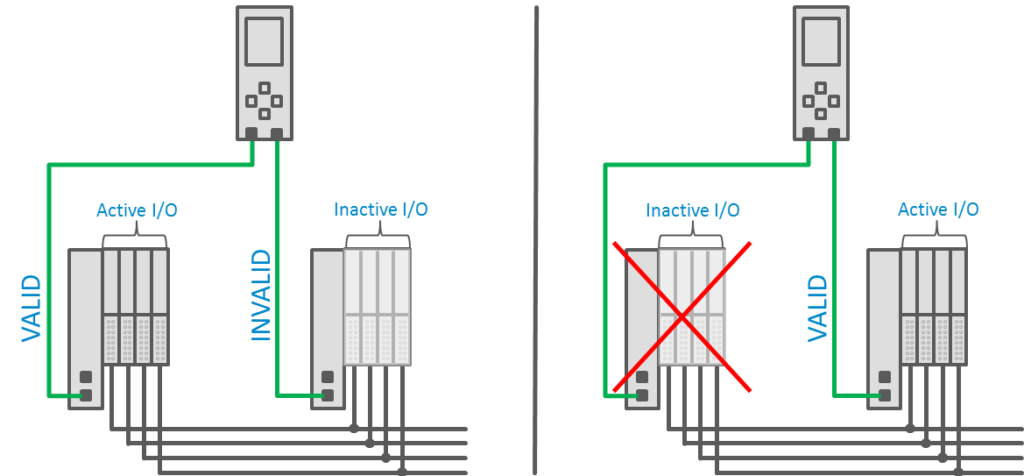

When a redundant pair of devices “fails over” from a primary device to a backup device, there’s usually some delay as the controller connects to the secondary device, parameterizes it, and then begins data exchange. PROFINET allows controllers to eliminate this delay. A controller can establish a connection with both devices simultaneously and send the same output data to both devices. However, it marks the data it sends to the secondary device as “invalid” while the data it sends to the primary is “valid”. When a failover is triggered on the controller, all it has to is mark the secondary output data as “valid,” and the secondary device can take over from the primary seamlessly and without delay.

On the left is a normal redundant system, with a connection exchanging valid data to a device with active I/O connections and a connection with invalid data to a device with inactive I/O connections. The system on the right shows a failure of the original “primary” device, and the new primary device exchanging valid IO data with active I/O modules.

Device Redundancy can work with any PROFINET device

Since PROFINET controllers handle coordination and failover, all devices must do is to handle valid and invalid IO data properly. That keeps things simple for device manufacturers, and means that all certified PROFINET devices can implement this kind of redundancy. Controllers usually support device redundancy with some special functions or APIs. But because PROFINET allows a lot of flexibility, it may be possible to implement redundant devices without special features. If you’d like to add device redundancy to your PROFINET system, check with your controller vendor to see how they’ve implemented it.

Continue your education by completing a PROFINET Certified Network Engineer Course.

Continue your education by completing a PROFINET Certified Network Engineer Course.

These certification classes are intense, hands-on courses. You will learn how the underlying technology works from the application to the frame level. After passing both a practical and written exam, you become certified.

For more information, contact us or visit our website.