When we talk about PROFIdrive, it’s always fun to use high-speed servos, CNC milling, and 3-D printing as application examples. But those applications are only some of the ways we use motors in the real world. Every day, millions of motors and drives are dedicated to pumping, blowing, and turning at a fixed speed. That’s what Application Class 1 drives are for – they’re PROFINET devices that don’t need high-speed, synchronized I/O or external control loops. AC1 PROFIdrive devices can operate with the most basic PROFINET conformance class at relatively long cycle times. Suitable for low-overhead drive control on low-cost PLCs.

Where an Application Class 1 Drive fits

AC1 drives can fit in a diverse set of applications. For instance, imagine a ski lift that operates at a constant speed setpoint. The drive running the prime mover is responsible for receiving the setpoint from the PLC, maintaining it with internal controls, and reporting the actual speed back to the PLC. The PLC will send some control commands along with that setpoint to the drive, like RUN, STOP, BRAKE, JOG, etc. It may also acknowledge or clear drive faults if they happen to occur.

Cyclic Data for PROFIdrive Application Class 1

| Name | Format | Description |

|---|---|---|

| Normalized Setpoint (e.g. NSOLL_A, NIST_A) | uint16 | A speed setpoint expressed as a percentage of the maximum rated speed of the drive. Values range from 0x0 - 0x4000. |

| Control Word (e.g. STW1, ZSW1) | uint16 | A control word used as a bitfield to issue commands like START, STOP, JOG, FAULT ACK, and others. |

The same PLC control can run a blower motor in a positive-pressure plenum serving a hospital’s operating rooms, or pumps keeping a holding tank topped off. Because PROFIdrive uses a common application interface, the drive interface doesn’t change, even between different drive manufacturers.

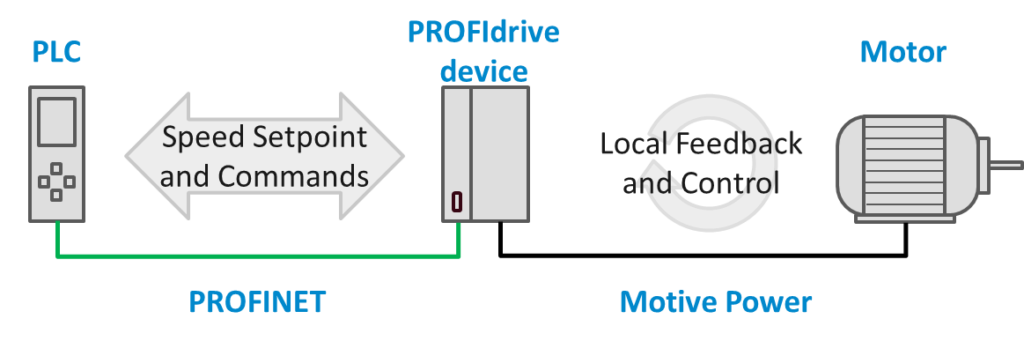

An AC 1 PROFIdrive device handles all of the motor feedback and controls locally. The PLC sends a speed setpoint and commands the drive to run, stop, jog or clear a fault.

An Example: A constant-speed pump

When a manufacturer implements an AC1 PROFIdrive device, they can include nameplate or inspection data from the attached motor or the drive may import that data from the motor. Either way, the drive will know the critical motor parameters, like its maximum rated speed and torque.

Because PROFIdrive is designed to be flexible across many different types of drives and motors, it uses this information on the drive to save a little processing in the Controller. The PLC usually transmits the speed setpoint in PROFIdrive as a “normalized” variable, with a range from 0% – 100%. So, an application running on a Controller will never be able to command a drive to spin a motor above its rated speed.

PROFIdrive without IRT

Application Class 1 drives can be implemented on PROFINET Conformance Class A, B, or C devices, and rely on the drive to provide internal control loops. With Application Class 1, the PLC is only a gateway to a broader automation system. It ties the PROFIdrive device to external sensors, actuators, and HMIs. It’s the easiest Application Class to get started with and is certainly the easiest to implement in a device.

Include application example (e.g. what values of NSOLL to use for 30% speed)

Gain a deeper understanding of PROFINET by attending a PROFINET Certified Network Engineer Course.

Gain a deeper understanding of PROFINET by attending a PROFINET Certified Network Engineer Course.

These certification classes are intense, hands-on courses. You will learn how the underlying technology works from the application to the frame level. After passing both a practical and written exam, you become certified.

For more information, contact us or visit our website.