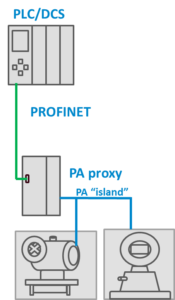

PA networks are designed to be operated as process “islands” within a larger PROFIBUS DP controlled network. The total network could consist of several of these “islands” all controlled by a single PLC/DCS. Each PA “island” starts with the DP/PA coupler which acts as the PA master and consists of several PA devices on a segment. Each “island” could be either intrinsically safe or non-intrinsically safe. PROFINET PA profile 4.0 describes PA within the PROFINET framework.

PROFINET proxies

PROFINET proxies take advantage of the existing “islands” that were created under the original PROFIBUS  PA concept. Each PA “island” network is accessed by the PROFINET controller as a single device. On the PA side, the proxy can act as the PA master (controller) and manages the communication coordination between the two physically different networks. Using a PROFINET proxy enables PROFINET to be extended into existing PA installations with minimum risk. The PROFINET PA proxy is functionally equivalent to the original DP/PA coupler from the PROFIBUS DP days. You can think of it as a “device” to the PROFINET controller and a “master” to the PA devices.

PA concept. Each PA “island” network is accessed by the PROFINET controller as a single device. On the PA side, the proxy can act as the PA master (controller) and manages the communication coordination between the two physically different networks. Using a PROFINET proxy enables PROFINET to be extended into existing PA installations with minimum risk. The PROFINET PA proxy is functionally equivalent to the original DP/PA coupler from the PROFIBUS DP days. You can think of it as a “device” to the PROFINET controller and a “master” to the PA devices.

PROFINET PA Profile 4.0

PA Profile 4.0 was designed to take advantage of PROFINET strengths and to incorporate the diagnosis concepts of PROFINET and PA into a unified system. There are several important advantages that PA Profile 4.0 with PROFINET has over the original PA with PROFIBUS DP. The following table compares PA stand alone, PROFIBUS DP and PROFINET features and capabilities.

| PROFINET PA Profile 4.0 | Feature Description |

|---|---|

| System Redundancy | PROFINET can support more than one connection to the controller. Allows higher availability for the network devices. |

| Media Redundancy | The network can be created as a ring that can continue to operate when one line in the ring is cut. Allows higher availability for the network devices. |

| Diagnosis severity | Extends diagnosis capabilities and reporting to show status of Good, Advise, Out of specification, Maintenance required, Maintenance demanded, and Fault. |

| CiR (Configuration in Run) | Allows the addition, removal, replacement, and re-parameterization of a device while the system is running. |

| PROFINET clock synchronization | Allows causal analysis of errors based on time. |

Process Automation Control

PROFINET can be used to make Process Automation systems more robust. Network availability and flexibility can be maximized by the system designer depending on requirements. The designer can weigh the feature cost impact to make an informed choice about the Process Automation implementation.

Do you want to learn more about PROFINET?

Do you want to learn more about PROFINET?

The PROFI Interface Center has you covered with PROFINET Certified Network Engineer classes.

Our certification classes are intense, hands-on courses. You will learn how the underlying technology works from the application to the frame level. After passing both a practical and written exam, you become certified.

For more information, contact us or visit our website.