Hazardous environments are areas where flammable liquids, gases or vapors or combustible dust exist in sufficient quantities to produce an explosion or fire. In hazardous environments, specially designed equipment and special installation techniques must be used to protect against the explosive and flammable potential of these substances. (OSHA Publication 3073)

There are three factors which have to be present in order for there to be a flame or explosion possibility in hazardous environments. The three factors are fuel, oxygen, and heat (or ignition source). If anyone of the three is not present, then there is no explosion or fire hazard.

Two Approaches in Hazardous Environments

1.-Employ explosion hardening methods in the system design

- Containment- Using cabinets strong enough to hold the explosion’s energy

- Isolation- Purging the potential explosive area of air by replacing it with an inert gas

- Avoidance- Moving all the control equipment outside the hazardous area

These hardening methods are sometimes too expensive or impractical to use.

2.-Use intrinsically safe components in the area to be protected

Intrinsic safety, (IS) is a protection technique for safe operation of electrical equipment in hazardous areas by limiting the energy available for ignition. In some cases signal and control circuits that can operate with low currents and voltages. For those, the intrinsic safety approach simplifies circuits and reduces installation cost over other protection methods. One reason for using intrinsically safe devices in an installation is that the devices will not generate a fire or explosion hazard due to the guaranteed limit on the stored energy.

Ethernet = not Intrinsically Safe

IEEE 100BASE-TX Ethernet (“4-wire Ethernet”) is the base technology for PROFINET. In order to access fields of application within Process Automation in hazardous areas, it is necessary to specify an intrinsically safe version as an extension to the IEEE 100BASE-TX standard. Fiber optics are an option, but devices still need power, meaning extra wiring costs and accompanying voltages that wouldn’t be intrinsically safe anyhow.

Intrinsic Safety with PROFINET

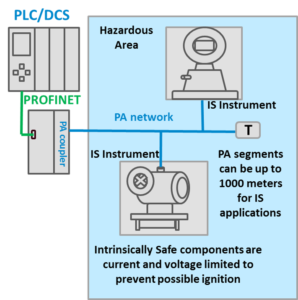

The current PI approach to IS uses PROFIBUS PA (PA) to meet intrinsically safety needs.  PROFINET uses a PROFIBUS PA proxy to connect to the PA system network.

PROFINET uses a PROFIBUS PA proxy to connect to the PA system network.

The advantages of PA are:

- PA works over a single twisted pair cable that provides both power and communication.

- It can communicate up to 1000 meters(1900 meters for non-IS).

- A single PROFINET to PA proxy can support multiple PA segments, each with the maximum PA bus distance.

Changes are in the works with extensions to the IEEE 100BASE-TX standard and with the PROFINET standard. This work is ongoing at the respective international standardization committee levels.

Gain a deeper understanding of PROFINET by attending a PROFINET Certified Network Engineer Course.

Gain a deeper understanding of PROFINET by attending a PROFINET Certified Network Engineer Course.

These certification classes are intense, hands-on courses. You will learn how the underlying technology works from the application to the frame level. After passing both a practical and written exam, you become certified.

For more information, contact us or visit our website.