In general, the process automation industry has many complex requirements. Due to complex automation processes and high restart costs, some process networks require continuous production; device introduction, replacement or re-parameterization without interruptions. The original PROFIBUS Configuration in Run (CiR) specification addressed this requirement. In fact, CiR provides the ability to reconfigure, insert, remove, or replace devices or modules without stopping the control application. There is no need to shut down or interrupt the network for plant repairs, modifications, or expansions.

The term “Configuration in Run” originated as part of the PROFIBUS DP and PA definitions. PROFIBUS CiR required “CiR objects” as placeholders in the system configuration. The Engineering tool defines these objects to create a dummy resource with memory and time allocations. These objects can be replaced on the fly and do not require a completely new download of all the system data.

PROFINET: CiR and Dynamic Reconfiguration

The PROFINET Profile release from 2017 describes how PROFINET accomplishes “bumpless” transitions. PROFINET does not have the same operational restrictions as PROFIBUS, creating dummy objects and hardware placeholders are not necessary. The new PROFINET profile changed the name of the “bumpless” transition process to Dynamic Reconfiguration (DR) to reflect that it does not work the same way PROFIBUS CiR did. PROFINET CiR and PROFINET DR are the same thing. For reference, the CiR/DR document is available for download here.

Dynamic Reconfiguration

DR is an optional PROFINET feature. In order to use the DR feature, the Engineering tool, the IO Controller, and any devices involved must support DR. But, mixed networks with DR and non-DR supporting devices are possible.

Requirements for CiR / DR support:

- System Redundancy (SR) must be supported by the IO controller and the device.

- The device and the IO controller must allow multiple Application Relations (ARs) (an Application Relation is the connection rules for communicating between a device and the IO controller.

- The device GSD has to support both DR and SR.

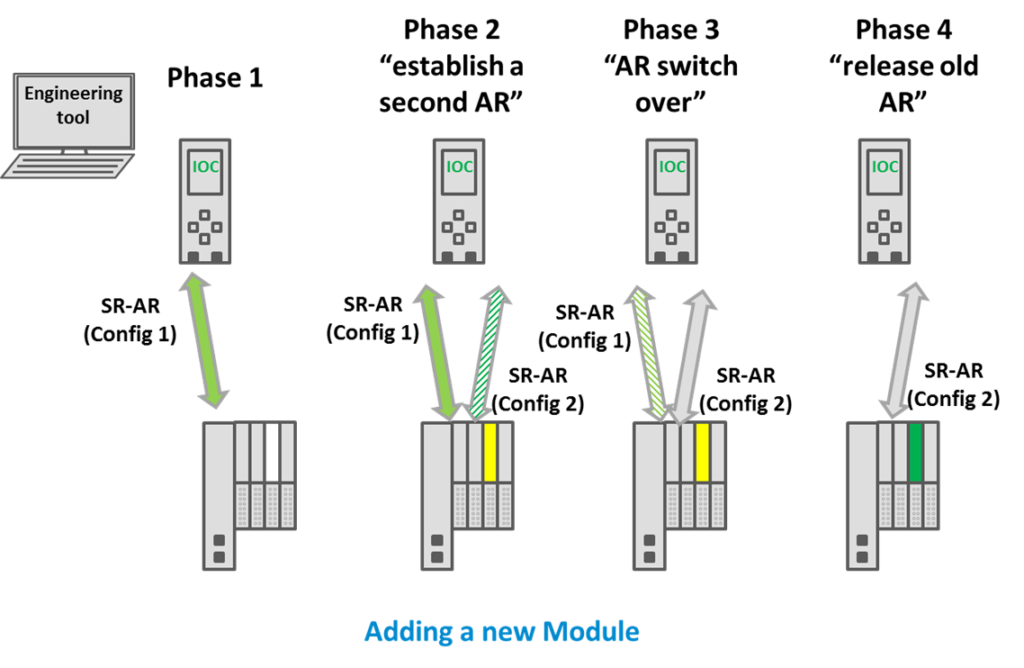

DR Mechanism Phases

- Initial phase Config 1 is the configuration controlling IO data, record data, and alarms

- Engineering tool initiates DR phase “establish a second AR” with new Config 2; the original AR still controls the IO

- Engineering tool initiates DR phase “AR switch over”; the second AR (with config 2) becomes the new controlling AR

- Engineering tool initiates DR phase “release old AR”; the AR with Config 1 is removed (in case of new modules, the IO device sends “plug alarm” to notify the IO controller that a new module is there)

PROFINET DR /CiR Allows Bumpless Changes on the Run

In cases where a system must support adding, changing or re-parameterizing devices (or modules) without causing a disturbance in system control, Dynamic Reconfiguration fits the bill. Choosing parts that support DR can enable operation across system maintenance, modifications, and expansions with minimum fuss. Altogether, CiR/DR allows the utmost flexibility in an installation for whatever the future might bring.

For more information, download the full White Paper:

For more information, download the full White Paper: