Safety PLCs are special controllers built and certified to meet international safety requirements such as NFPA 79, IEC 62061, IEC 13849-1 or IEC 61508. All of these safety standards define levels of risk reduction.

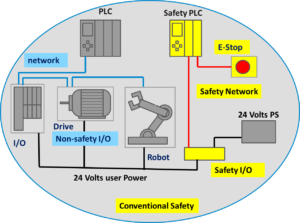

Conventional Safety PLC Principle

The original safety PLC concept required that normal PLCs and standard I/O could not be mixed with safety PLCs and safety components in the same network. This approach resulted in duplication of wiring for safety and non-safety functions and the added headache of coordination between the two separate systems. This approach is sometimes called “conventional safety” and is illustrated in the following figure.

Components of Conventional Safety System

- PLC/DCS with control program

- PLC/DCS engineering tool/programmer

- Standard I/O

- Communication Bus (non-safety)

- Specialized Safety PLC with safety program

- Specialized Safety engineering tool/programmer

- Safety Components (I/O, switches, actuators with safety functions built-in, light-curtains, laser scanners)

- Separate Safety-only Bus

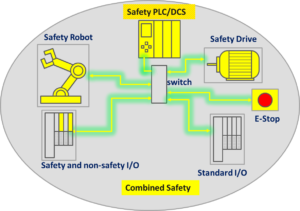

Combined Safety PLC Principle

Maintaining separate bus wiring for both the standard PLC and I/O and the safety PLC and I/O proved to be expensive. Using only the safety PLC and safety I/O to handle standard and safety I/O was also expensive(Safety I/O is quite a bit more costly than standard I/O, if safety is not required, why pay for it?). The best cost savings came with the idea of sharing the safety PLC and I/O bus for both safety and standard functions.

Components of Combined Safety System Design

- Safety PLC/DCS with a safety and non-safety program

- Safety PLC/DCS Engineering tool/programmer

- Standard I/O

- Components with built-in safety (I/O, switches, actuators with safety functions built-in, light-curtains, laser scanners)

- Common Communication Bus

Benefits of Combined Safety

Combining the safety and non-safety components in one system can save significant wiring costs. Using one safety PLC for all PLC/safety functions allows a single engineering tool for all programming. The combined approach saves costs and lowers the confusion factor associated with having multiple programming tools.

PROFIsafe Communications

PROFIBUS / PROFINET International (PI) created PROFISafe, the communication part of a combined safety system . Continue here for an overview of PROFIsafe basics. PROFIsafe Profile Overview

If you need some review on Safety, you can go here to the beginning of this discussion Safety Basics.

Gain a deeper understanding of PROFINET by attending a PROFINET Certified Network Engineer Course.

Gain a deeper understanding of PROFINET by attending a PROFINET Certified Network Engineer Course.

These certification classes are intense, hands-on courses. You will learn how the underlying technology works from the application to the frame level. After passing both a practical and written exam, you become certified.

For more information, contact us or visit our website.