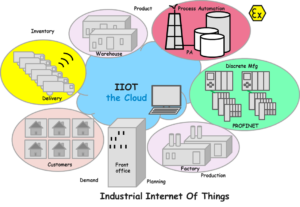

The Industrial Internet of Things (IIoT) is making direct access to process data at all levels more necessary by the day. End users, DCS and PLC manufacturers require process device data for control, monitoring, problem reporting, and inventory management simultaneously. There is a limit to the amount of data traditional fieldbuses like PROFIBUS PA can handle due to data packet maximums and low baud rates. PROFINET on the other hand, allows communication up to Gigabit Ethernet speeds with data virtually unlimited. In process automation, PROFINET continues expanding the feature set developed for PROFIBUS DP and PA. PROFINET is also bringing new features to the process world.

The Industrial Internet of Things (IIoT) is making direct access to process data at all levels more necessary by the day. End users, DCS and PLC manufacturers require process device data for control, monitoring, problem reporting, and inventory management simultaneously. There is a limit to the amount of data traditional fieldbuses like PROFIBUS PA can handle due to data packet maximums and low baud rates. PROFINET on the other hand, allows communication up to Gigabit Ethernet speeds with data virtually unlimited. In process automation, PROFINET continues expanding the feature set developed for PROFIBUS DP and PA. PROFINET is also bringing new features to the process world.

PROFIBUS DP and PA in Factory Automation

PROFIBUS DP broke new ground with its diagnostic reporting mechanisms. Diagnostics reporting was handled with event-driven communication techniques. PROFIBUS was adapted to the process world through the addition of PROFIBUS PA. PA grew into its place in the process market with the user-friendly profile mode which allowed PA devices from one vendor to replace similar devices from other vendors operating in profile mode. PA profile 3.02 introduced adaptation mode which lets new PA instruments detect that they are replacing old version PA devices from the same vendor and to perform like they are the older device. This allows new devices to replace aging ones without having to make any change to controlling PLC hardware or software.

PROFINET and Process Automation

PROFINET uses reporting mechanisms to asynchronously send and receive device status and diagnostic information. It also supports redundancy, diagnosis/alarm level severity and Configuration in Run. These features are considered nec essary by the User Organization of Automation in Process Industries (NAMUR). PROFINET does not have the intrinsic safety (explosion prevention) of PROFIBUS PA, but that is not a limitation of PROFINET, but of Ethernet. In order to fully serve the process industries more technical work will need to be done on Ethernet at the field level, specifically long cable runs (up to 1,000 meters), 2-wire technology, loop power, and of course intrinsic safety.

essary by the User Organization of Automation in Process Industries (NAMUR). PROFINET does not have the intrinsic safety (explosion prevention) of PROFIBUS PA, but that is not a limitation of PROFINET, but of Ethernet. In order to fully serve the process industries more technical work will need to be done on Ethernet at the field level, specifically long cable runs (up to 1,000 meters), 2-wire technology, loop power, and of course intrinsic safety.

All in all, PROFINET is making process automation data available to upper-level applications. PROFINET connectivity to PROFIBUS PA is making process automation data easily available by allowing the connection of existing PA devices to higher levels of control. Also, as new PROFINET features are enhancing PA availability, direct connection to process instruments is coming closer to be a reality.

Do you want to learn more about PROFIBUS or PROFINET?

Do you want to learn more about PROFIBUS or PROFINET?

The PROFI Interface Center has you covered with PROFIBUS and PROFINET Certified Network Engineer classes.

Our certification classes are intense, hands-on courses. You will learn how the underlying technology works from the application to the frame level. After passing both a practical and written exam, you become certified.

For more information, contact us or visit our website.