PROFIBUS PA is a slowly-transitioning, low-volume data network for Process Automation, based on Manchester-encoded Bus-Powered for Intrinsic Safety (MBP-IS). The rate of data change is within the range of tens-of-milliseconds to multiple seconds. A PROFIBUS PA network operates over a single cable that provides power and communication. In contrast, PROFINET is a high-speed, high-volume data network for Industrial Automation, based on Ethernet technology. The rate of data change is on the order of sub-millisecond. PROFINET is the ideal transport mechanism to move information and control data from existing PROFIBUS PA installations to higher level control systems. PROFINET for PA allows control data and related information to be seamlessly integrated from the front office to the farthest instrument.

PROFINET PROFIBUS PA Feature Comparison

| PROFINET | PROFIBUS PA | |

|---|---|---|

| Data packet size | Up to 1500 bytes | Up to 244 bytes |

| Transfer speed | 100 Mbit/s - 1 Gbit/s | Fixed at 31.25 kbits/s |

| Physical media | 4-wire copper, fiber optic cable, wireless | Manchester Bus Powered Intrinsically Safe (MBP-IS) |

| Device power source | External power or Power Over Ethernet (PoE) | MBP-IS over PA bus (External power source possible) |

| Number of I/O devices available | Unlimited | 122 devices total per PA network |

| Maximum distance between devices | Up to 100 meters between devices | Up to 1000 meters total for Intrinsically Safe segment |

PROFIBUS PA Installations

Formerly, PROFIBUS PA replaced 4-20 mA technology with a single (power over the cable) fieldbus. Also, the transition from hundreds of individual wires to a single wire for all networked instruments meant big saving in hardware costs. Many of the instruments were purposefully designed to update slowly so as to not cause feedback loops and data fluctuations. For variables like temperature, level, and pressure transmitters these were good choices. Since then, millions of PROFIBUS PA devices have been sold and are currently being used in process applications around the world.

PROFIBUS PA is limited in the amount of data a single instrument can transmit to 244 bytes of Inputs and 244 bytes of Outputs at the fixed baud rate of 31.25 kbits/sec. PROFIBUS PA networks run through a DP/PA Coupler. The PROFIBUS DP provides the master functionality, the coupler is the gateway between the two related protocols. It synchronizes the differences between the baud rates and provides the power and signal for the PROFIBUS PA network.

PROFINET and Legacy Systems

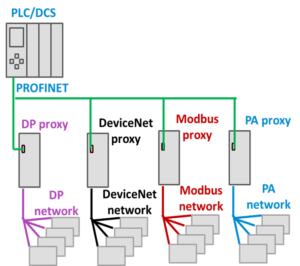

The original concept for PROFINET access to legacy systems was to use proxies (gateways) to connect to the legacy system. Some of the original legacy systems supported were PROFIBUS, DeviceNet, and Modbus. Due to the speed and data size differences between PROFINET and the more limited legacy systems, the proxies are modeled as a device on the PROFINET side and a controller on the legacy side. Originally, the connection to PA was to first use a PROFIBUS DP proxy and then connect a DP/PA Coupler on the PROFIBUS network. This is still a viable solution, however, several vendors have developed direct PROFINET to PROFIBUS PA couplers and they are available now as PROFINET devices. This more direct approach removes the need for any PROFIBUS DP wiring or hardware in the installation.

PROFINET makes the transition to Process Automation using DP or PA proxies. PROFINET for PA makes information and control from the process automation areas available to higher level PLCs, DCSs, SCADAs, and other systems.

Do you want to learn more about PROFINET?

Do you want to learn more about PROFINET?

The PROFI Interface Center has you covered with PROFINET Certified Network Engineer classes.

Our certification classes are intense, hands-on courses. You will learn how the underlying technology works from the application to the frame level. After passing both a practical and written exam, you become certified.

For more information, contact us or visit our website.