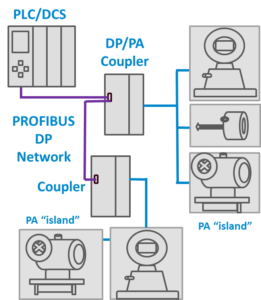

PROFIBUS PA ( Process Automation) was designed to work along with PROFIBUS DP (Decentralized Periphery) to make a consolidated network using DP for high-speed communications and PA for process environment. A network consists of a DP master (controller), a DP segment, a DP/PA coupler and the process network with slave devices.

Fast DP controllers connected to slow PA instruments. How does that work? The device that brings DP and PA together is called a coupler. While the physical layers are very different for each network, the content of the communication telegrams is the same. The DP/PA coupler translates the signals between the different physical layers and provides data coordination at the interface between the parts of the network.

DP and PA Device Setup

The setup of devices for input and output is based on GSD files (General Station Description) that describe all available features for data communications by the devices. The GSDs are used by the configuration tool to specify the input and output configurations of the device. The tool used depends on the vendor of the PLC / DCS being used for the controller.

PA Engineering Tools

There are “additional” features inside PA devices that are accessed by specialized engineering tools These features are things like temperature units, pressure units, alarm levels, and asset tags. One type of engineering tool uses Electronic Device Description Language files (EDDLs) to describe the available features of the device. PDM from Siemens uses EDDLs . The other type of engineering tool uses Device Type Manager files (DTMs) to access PA features. PactWare and FieldCare use DTMs.

High-speed Network

Originally, PROFIBUS DP was to be the main network trunk with PA branches (sub-networks). PROFINET was designed to be the successor technology to DP so PROFINET also became the replacement backbone instead of DP at the trunk level of the network. PROFINET and the PA profile 4.0 bring additional possibilities for PA operations with improvements to the original DP in connection-technology and speed. The following table shows PROFIBUS PA, PROFIBUS DP, and PROFINET features to allow a head to head comparison of all three.

PROFIBUS PA DP and PROFINET comparison

| PROFIBUS PA | PROFIBUS DP | PROFINET | |

|---|---|---|---|

| Communication technology | MBP-IS | RS-485 | Ethernet |

| Bandwidth | 31.25 kbps | 9.6 kbps to 12 Mbps | 100 Mbps |

| Typical distances | up to 1900 m total (1000 m for IS) | 100 m at 12 Mbps | up to 100 m between connections |

| Network topology | line, star, tree | line (daisy-chain) | line, star, tree, ring for redundancy combination |

| Fiber optical available? | no | yes | yes |

| Data packet size | up to 244 bytes | up to 244 bytes | up to 1440 bytes |

| Number of stations on network | 64 devices | up to 126 devices | unlimited |

| Intrinsically Safe | optional | optional, limited to RS-485 IS devices and infrastructure. | optional / planned |

For more information, download the full White Paper:

For more information, download the full White Paper: