In the automation environment of today and tomorrow, end users need a system which is built with effective diagnostic capabilities and is easy to manage at both the network and application levels for minimum downtime and increased productivity. PROFINET should be your network of choice because it has best in class diagnostic mechanisms which are in short: ‘suite and simple’.

IT PROTOCOLS

The diagnostics ‘suite’ comes from PROFINET being built on standard IEEE 802.3 Ethernet allowing the use of Information Technology (IT) protocols such as Simple Network Management Protocol (SNMP), Link Layer Discovery Protocol (LLDP), and Hyper Text Transport Protocol (HTTP) as part of its communication architecture. This is a plus for PROFINET and different from competing protocols as most of the time this information is built directly into the devices by design and tested in products that support it, hence making network management on PROFINET much more reliable and stable. In addition, the PROFINET application protocol has a focus on diagnostics which can provide details about the application and process. This suite of protocols makes diagnostics easier for the user to implement their application without having to write their own diagnostic protocols and specific routines for the application.

The diagnostics ‘suite’ comes from PROFINET being built on standard IEEE 802.3 Ethernet allowing the use of Information Technology (IT) protocols such as Simple Network Management Protocol (SNMP), Link Layer Discovery Protocol (LLDP), and Hyper Text Transport Protocol (HTTP) as part of its communication architecture. This is a plus for PROFINET and different from competing protocols as most of the time this information is built directly into the devices by design and tested in products that support it, hence making network management on PROFINET much more reliable and stable. In addition, the PROFINET application protocol has a focus on diagnostics which can provide details about the application and process. This suite of protocols makes diagnostics easier for the user to implement their application without having to write their own diagnostic protocols and specific routines for the application.

Since PROFINET uses standard Ethernet it means that the network can support many protocols at the same time and multiport switches are used (which are typically built directly into the devices). Therefore, diagnostic methodologies from the office world and IT can then be leveraged and information obtained from the device(s) at any time. And many Industrial PROFINET products also support this so you can make use of this data on your Human Machine Interfaces (HMI).

SNMP

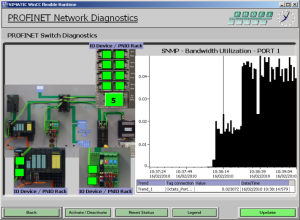

This is where the term “simple” comes in for simple network management when using PROFINET. The SNMP protocol can be used to gather information from the network components (switches and devices) and let control engineers know the current status of the network health (Fig 1). The reason SNMP is called “simple” is that it is based on a polling protocol which supports up to nine commands, the most common are get, set, get bulk, response, inform, trap, etc., and can read data from the devices using off the shelf tools over User Datagram Protocol (UDP/IP) and in some special cases write information. Your local IT department likely already has something like this, so your first resource for SNMP might be internal, otherwise many other companies offer SNMP tools and information. Some tools can even be obtained free of charge but without the support and commercial versions might have more features and support included. We often use the tools from PRTG in our classes for network management or SNMP OPC Servers from various vendors to obtain that type of information in HMIs which might not support SNMP natively.

Figure 1: Reading SNMP info from device ports

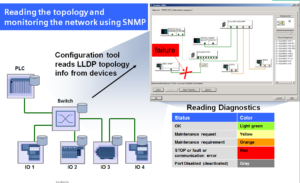

The types of information you can read with SNMP could be for instance, Cyclic Redundancy Check (CRC) errors, number of retransmits, bandwidth utilization, which is highly important when looking at network loads, or no link on the switch port (i.e. Port status). LLDP works in conjunction with SNMP to gather ‘topology’ information for network topology discovery or simple device replacement without special software tools (Fig 2).

HTTP

Another IT protocol, HTTP allows engineers to use just a standard web browser to see information about the devices with built-in web pages or to configure devices. Other devices might even offer other services such as email in case of an issue, File Transfer Protocol (FTP) to copy files like a project or PROFINET GSD file, or a telnet connection to do configuration through a basic command interface.

Figure 2: Reading Topology diagnostics and network status from devices

We’ll cover more about LLDP, DCP, and network management features in part 2. Remember to check with your vendor on these features to understand how to best employ them in your applications.

In conclusion, PROFINET has the most collective and comprehensive diagnostics suite available of any Industrial Ethernet protocol. This helps make it easy to manage your network, implement diagnostics in your applications, and keep downtime to a minimum.

To learn more and see how simple it is and learn firsthand, attend one of our hands-on PROFINET Certified Network Engineer classes in the near future.

Continue your education by completing a PROFINET Certified Network Engineer Course.

Continue your education by completing a PROFINET Certified Network Engineer Course.

These certification classes are intense, hands-on courses. You will learn how the underlying technology works from the application to the frame level. After passing both a practical and written exam, you become certified.

For more information, contact us or visit our website.