A PROFINET network can be a complex collection of stations, from digital I/O devices to pneumatic actuators to laser scanners… the list seems endless and grows every day. But within that complex network, all PROFINET components operate within three different roles. They can be either Devices, Controllers, or Supervisors. These roles aren’t based on what a component is doing in the real world. Instead, they’re based on how each component interacts with all of the others on the network. These are foundational to PROFINET basics.

PROFINET Node Roles

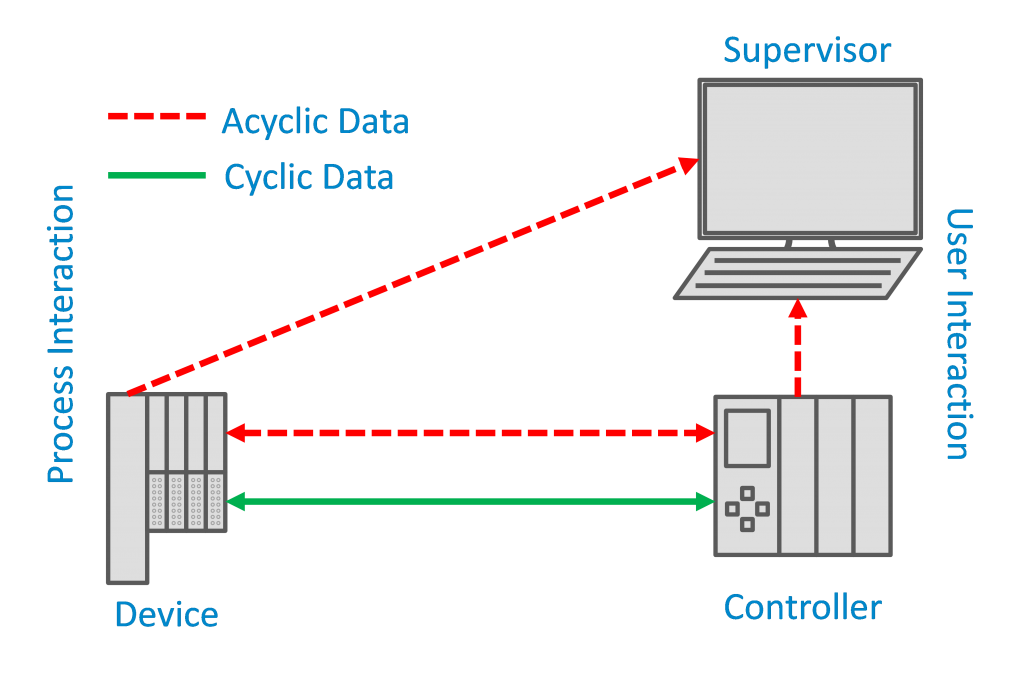

- Devices are stand-alone units designed to communicate real-time information to a Controller. They don’t don’t try to communicate with other devices directly. Instead, they report their real-time (cyclic) data directly to a Controller and may send some alarm or diagnostic (acyclic) data to a Supervisor.

- Controllers are aggregators for real-time (cyclic) data sent by one or more Devices. They keep up not only with a device’s real-time data, but they collect information about each device’s maintenance status, collect alarm messages, and make all of that information available to an end-user. Controllers are typically PLCs, PC software applications, or high-end HMIs.

- Supervisors are similar to Controllers, but they don’t have access to the real-time data from any Device. Supervisors are not part of the daily operation of a PROFINET network. Instead, end users may use a Supervisor to do things like read diagnostic information from a Device, assign IP addresses or DCP station names, or troubleshoot a problematic network connection.

Real World Examples

It’s pretty straightforward: Most PLCs that implement PROFINET are Controllers, and most of the components that interface with the real world are Devices. Supervisors are typically included with the PLC manufacturer’s configuration utility (TIA Portal, Proficy ME, PC Worx, etc), though some products combine the Controller and Supervisor roles. PROFINET Commander, for instance, incorporates both Supervisor and Controller capabilities into one software package.

A word of warning: while the capabilities of a PROFINET Device and Controller are defined by the PROFINET specification, there’s no specification for a PROFINET supervisor. So, if you’re counting on a particular Supervisor set of capabilities, double-check the spec sheet before you purchase it.

Summary

PROFINET Devices typically sit out in the field and interact with a physical process. Controllers and Supervisors sit closer to an operator and aggregate information from Devices. Supervisors only interact with controllers or devices when directed to by a user application. On the other hand, controllers interact with devices on a regular basis as part of their normal operation.

DISCLAIMER: The author works with the PROFINET Commander team and has an interest in promoting the product. There may be similar products available on the market, but he’s not familiar with them.

Gain a deeper understanding of PROFINET by attending a PROFINET Certified Network Engineer Course.

Gain a deeper understanding of PROFINET by attending a PROFINET Certified Network Engineer Course.

These certification classes are intense, hands-on courses. You will learn how the underlying technology works from the application to the frame level. After passing both a practical and written exam, you become certified.

For more information, contact us or visit our website.